Wednesday, 24 February 2016

|

Contact Person: hui hou

Address: Poli Industrial Park, Huangdao District, Qingdao, China

qingdao , shandong , China - 266000

Phone:3288885868

Mobile:17306399132

Email: admin@sanzhuji.com

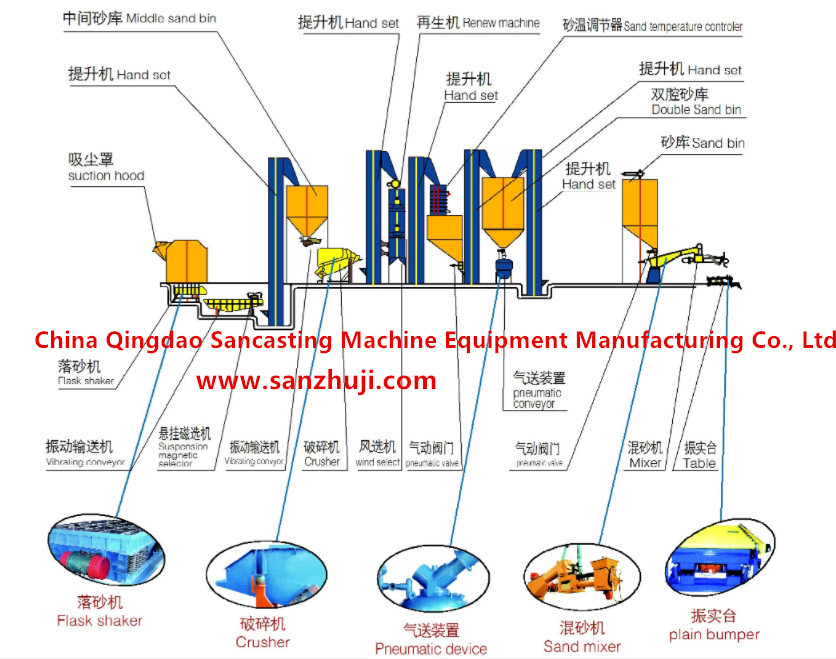

Resin sand is resin as the binder configuration of type (core) sand, old sand regeneration is the maximum removal of the surface of the sand binder film, sand surface (particle size) adjustment, it is very economical to replace the new sand that will be used. The recycling of old sand can save the consumption of new sand and the transportation cost for throwing away old sand, and the recycling of sand is even. The surface is smooth and the heat is hidden. It is beneficial to improve casting quality, especially to reduce the amount of resin added when the old sand is recycled and reduce the cost of resin. It can also reduce environmental pollution caused by discharged waste sand. Mail: admin@sanzhuji.com Web: www.sanzhuji.com

Resin sand is resin as the binder configuration of type (core) sand, old sand regeneration is the maximum removal of the surface of the sand binder film, sand surface (particle size) adjustment, it is very economical to replace the new sand that will be used. The recycling of old sand can save the consumption of new sand and the transportation cost for throwing away old sand, and the recycling of sand is even. The surface is smooth and the heat is hidden. It is beneficial to improve casting quality, especially to reduce the amount of resin added when the old sand is recycled and reduce the cost of resin. It can also reduce environmental pollution caused by discharged waste sand. Mail: admin@sanzhuji.com Web: www.sanzhuji.com

The advantages of the air box pulse bag dust collector, such as chamber blowback and pulse jet blowback, overcome the kinetic energy of chamber blowback due to the lack of strength and the disadvantages of simultaneous filtration and ash removal, the bag dust collector has increased its applicability and efficiency. Equipment features: The dust removal efficiency can reach above 99.9, and the dust emission can be controlled below 30mg/m. It can handle high concentration and high dust below 100g/m3. Advanced sealing measures, air leakage coefficient less than 2%; Advanced structure design, large filter area per unit volume, small size of equipment, unique and effective way of ash removal, prolong the service life of filter bag: key parts of reliable quality, long service life, stable performance, high degree of automation, simple daily maintenance and management. Mail: admin@sanzhuji.com Web: www.sanzhuji.com

S33 series sand crusher is the fourth generation crusher developed by our company. The device sets crushing, Screening, primary regeneration as a whole. Compared with the built-in crusher, this machine has the advantages of reliable use, simple structure and convenient maintenance. Mail: admin@sanzhuji.com Web: www.sanzhuji.com

This filter uses circular uniform structure, form good antiknock performance, compact structure, adopting high pressure fan blow soot cleaning, without being limited by the conditions of gas source, using resistance automatic control counter blowing dust to save energy and prolong the service life of the bag. Cold region indoor installations can be installed outdoors, and other areas can be widely used in machinery, casting, mining metallurgy, building materials, food chemical industry and many other departments. Working principle: The dust gas enters tangentially into the upper space of the filter chamber. Under the action of centrifugal force, large particles and agglomerated dust particles rotate along the simple wall and fall into the dust bucket. Small particles of dust are dispersed in the air space between the bags in the filter chamber and thus are retained by the filter bag. The purified air is collected in the cleaning room through the bag wall through the filter bag inlet on the flower plate and then inhaled and discharged by the ventilator. With the continuous filtration condition, the dust trapped on the surface of the filter bag gradually increases, and the resistance of airflow gradually increases. When the set resistance limit is reached, the automatic control device will turn on the back-blown cleaning machine to clear the dust. Mail: admin@sanzhuji.com Web: www.sanzhuji.com

The process of shell type steel filling (dry sand) is to put the shell type into the barrel and fill the steel balls (dry sand) around the barrel to reinforce the shell A casting process in which a mold is formed and a molten iron is cast. Castings are cooled by steel pellets, the faster the cooling speed, the better the air permeability, the better the recovery of steel pellets, the smaller the equipment investment, the slower the die consumption, and the easier the mold change. Mail: admin@sanzhuji.com Web: www.sanzhuji.com

The FD series of compressed air purification dust remover realizes automatic continuous cleaning through compressed air, and the stable filter pressure difference ensures the safe operation of the dust remover. Compared with FS backblow air purification dust collector, its investment cost is low. The cleaning pulse is controlled by electricity and pneumatic, and the cleaning time and interval time can be adjusted. Mail: admin@sanzhuji.com Web: www.sanzhuji.com

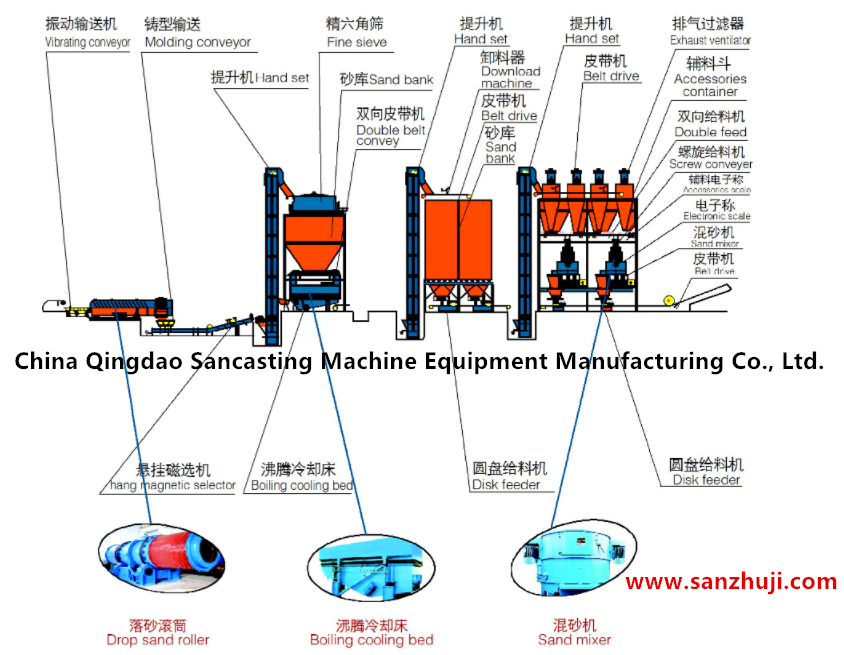

Clay sand is the molding sand with clay as the binder. Sand treatment department is an important part of the foundry. Its main task is to provide qualified molding sand for the molding core-making department. The preparation of molding sand has a direct impact on the quality of casting production, the increase of output and the reduction of cost. Due to the complexity of sand treatment process, the workload of clay sand treatment and transportation is very large, and the environment is very harsh, so the realization of sand treatment process mechanization is an important part of casting production. Mail: admin@sanzhuji.com Web: www.sanzhuji.com

The advantages of the air box pulse bag dust collector, such as chamber blowback and pulse jet blowback, overcome the kinetic energy of chamber blowback due to the lack of strength and the disadvantages of simultaneous filtration and ash removal, the bag dust collector has increased its applicability and efficiency. Equipment features: The dust removal efficiency can reach above 99.9, and the dust emission can be controlled below 30mg/m. It can handle high concentration and high dust below 100g/m3. Advanced sealing measures, air leakage coefficient less than 2%; Advanced structure design, large filter area per unit volume, small size of equipment, unique and effective way of ash removal, prolong the service life of filter bag: key parts of reliable quality, long service life, stable performance, high degree of automation, simple daily maintenance and management. Mail: admin@sanzhuji.com Web: www.sanzhuji.com

Since its establishment, Qingdao Sanzhuji Equipment Manufacturing Co.,Ltd. has been committed to the design, development and manufacture of sand processing equipment, resin sand production line, clay sand production line, molding line and other casting machinery. Qingdao Sanzhuji Equipment Manufacturing Co.,Ltd. is one of the production bases of shot blasting machine with complete varieties, high technical content and large production and sales volume in China's casting machine industry. The products sell well in China and are exported to Southeast Asia, India and other countries and regions. Professional and technical personnel are composed of senior engineers, senior technicians with rich practical experience in manufacturing and technical workers who have worked for many years. The products of the company, such as shot blasting machine, road shot blasting machine, resin sand production line and clay sand production line, all adopt CAD simulation auxiliary design, from the whole process of design, research and development, production and service monitoring, and all products are subject to archival management. Product sales and service network throughout the country. Main products: shot blasting machine, road shot blasting machine, resin sand production line, clay sand production line, environmental protection dust removal equipment and other casting machinery products. Mail: admin@sanzhuji.com Web: www.sanzhuji.com

Page Links |

||||