Wednesday, 24 February 2016

|

Contact Person: vanne singh

Address: 10/20, 1st floor, 6th khetwadi

Mumbai , Maharashtra , India -

Phone:91-022-67437816

Mobile:

Email: info@riddhisiddhi.net

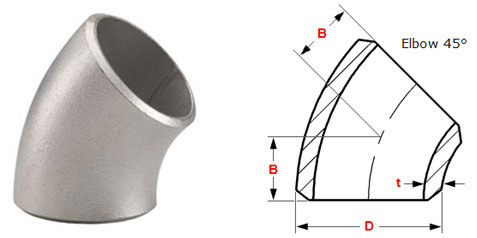

Duplex Pipe Fittings :- Duplex Pipe Fittings are the widely chosen fittings, used in critical conditions of industries. We have in our range tees, elbows, reducers, cap and crosses for various pipeline installation requirements. Widely demanded in the industries of oil & gas, petrochemical and many others, these fittings are designed with the assurance of dimensional accuracy, resistance against corrosion and high tolerance capacity. Designed in the options of threaded and socket weld end connections, the pipe fittings have either buttweld, seamless or welded construction. These have the ability to bear wide range of pressure level with excellent inertness to toxic chemicals. Best suited for highly critical applications where leakage can be hazardous, the pipe fittings are used in boilers, desalination plants and brewing tanks. There are minimum burrs at the edge of the fittings with excellent accuracy in dimensions even in high temperature range. Due to their high yield strength, these are widely demanded in petrochemical industry, nuclear industry, paper & pulp industry and defence sector. Technical Specifications : Schedules : 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS Size : 1/2" - 24"NB Finish : Hot dip galvanized, epoxy coated and electropolished Available with : NACE MR 01-75 Form : Elbows in long & short radius in 45 deg, 90 deg, 180 deg Eccentric reducer & concentric reducer Easy and quick to install Ensure tight and leak proof joints Direct the flow in a specific direction Remain inert to chemicals Prevents the entry of dirt and other impurities into the pipelines Accuracy in dimensions Smooth and long lasting finish Wear and tear resistant Use For : Fabricating pressure vessel for a moderate and elevated high temperature environment Application Areas : Petro-chemical industry Oil and gas industry Nuclear industry Pulp & paper industry Research & development Mega projects Defense industry Development industry

Duplex Pipe Fittings :- Duplex Pipe Fittings are the widely chosen fittings, used in critical conditions of industries. We have in our range tees, elbows, reducers, cap and crosses for various pipeline installation requirements. Widely demanded in the industries of oil & gas, petrochemical and many others, these fittings are designed with the assurance of dimensional accuracy, resistance against corrosion and high tolerance capacity. Designed in the options of threaded and socket weld end connections, the pipe fittings have either buttweld, seamless or welded construction. These have the ability to bear wide range of pressure level with excellent inertness to toxic chemicals. Best suited for highly critical applications where leakage can be hazardous, the pipe fittings are used in boilers, desalination plants and brewing tanks. There are minimum burrs at the edge of the fittings with excellent accuracy in dimensions even in high temperature range. Due to their high yield strength, these are widely demanded in petrochemical industry, nuclear industry, paper & pulp industry and defence sector. Technical Specifications : Schedules : 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS Size : 1/2" - 24"NB Finish : Hot dip galvanized, epoxy coated and electropolished Available with : NACE MR 01-75 Form : Elbows in long & short radius in 45 deg, 90 deg, 180 deg Eccentric reducer & concentric reducer Easy and quick to install Ensure tight and leak proof joints Direct the flow in a specific direction Remain inert to chemicals Prevents the entry of dirt and other impurities into the pipelines Accuracy in dimensions Smooth and long lasting finish Wear and tear resistant Use For : Fabricating pressure vessel for a moderate and elevated high temperature environment Application Areas : Petro-chemical industry Oil and gas industry Nuclear industry Pulp & paper industry Research & development Mega projects Defense industry Development industry

Size : 1/2"NB TO 48"NB IN Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS Type : Seamless / ERW / Welded / Fabricated Material Type : Stainless Steel, Alloy Steel and Carbon Steel Nickel Alloys Duplex Grades : Nickel Alloy ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) Stainless Steel ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H. Duplex Steel ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760. Carbon Steel ASTM / ASME A 234 WPB, WPC ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. Alloy Steel ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91.

Stainless Steel Pipe Fittings are high in demand in the market for use in highly corrosive industrial conditions. Available in wide varieties, ranging from small to large diameters, these pipe fittings are offered with maximum pressure rating. This property of the fittings makes these highly suitable for corrosive and critical industrial applications. Made in different SS grades that superior in quality, these pipe fittings ensure safe and secure material supply. Available as buttweld, threaded and socket weld fitting, these are offered to clients in wide varieties of sizes and wall thicknesses. With wide application in analytical and process instrumentation, plant utilities and CNG industry, these pipe fittings are highly suitable for pressurized applications. In our range, we have pipe fittings with different types of ends to ensure quick and tight joints in pipelines. There is excellent resistance in these fittings towards corrosion, chemicals and harsh weather conditions. Hence, assure uninterrupted and non- contaminated fluid or gaseous flow in the industries. Technical Specifications : Stainless Steel Pipe Fitting Grades : ASTM A403 Grade WP304, WP304L, WP304H, WP304N, WP304LN, WP309, WP310S, WPS31254, WP316, WP316L, WP316H, WP316N, WP316LN, WP317, WP317L, WP321H , WP321, ASTM A815 S31803, S32750, S32760, S32205 Standard Material Grades In Stainless Steel : ASTM A182 F304, F304H, F304L, F304N, F304LN, F309H, F310, F310H, F316, F316H, F316L, F316N, F316LN, F317, F317L, F347, F347H, F321, F321H, FXM-19, F50, F51, F53, F55, F60, F904L Inconel Forged Pipe Fittings : Size : 1/4" NB to 4" NB IN Pressure rating : 3000 LBS, 6000 LBS, 9000 LBS Available with : NACE MR 01-75

Alloy Steel Pipe Fittings are the best preferred fittings for installation of pipelines. All these fittings are made from the best grades of alloy steel with the strength to sustain highly hazardous chemicals and gases. These are best suited for sensitive applications in power generation and nuclear industries to handle toxic materials that are harmful to human and animals if leaked. Ensure easy and quick installation of the pipelines, these pipe fittings are available in wide sizes and pressure ratings with choice in surface finish. Available As: Forged Threaded Buttweld Seamless Technical Specifications : Thickness : SCH10-XXS Size : 1/2NB- 600NB Surface finish : Electro-galvanized, hot galvanized Construction materials : Alloy Steel Grades : ASTM A234 Grade WP1, WP12 CL1, WP12 CL2, WP11 CL1, WP11 CL2, WP11 CL3, WP22 CL1, WP22 CL3, WP5 CL1, WP5 CL3, WP9 CL1, WP9 CL3, and WP91 Standard Material Grades In Carbon Steel : ASTM A182 F1, F5, F 5a, F9, F91, F11 Class 1, F12 Class 1, F22 Class 1

Size : 1/2"NB TO 48"NB IN Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS Type : Seamless / ERW / Welded / Fabricated Material Type : Stainless Steel, Alloy Steel and Carbon Steel Nickel Alloys Duplex Grades : Nickel Alloy ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) Stainless Steel ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H. Duplex Steel ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760. Carbon Steel ASTM / ASME A 234 WPB, WPC ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. Alloy Steel ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91.

Blind Flanges :- These flat face steel blind flanges are used to blank off pipelines, valves and pumps, it can also be used as an inspection cover. Blind flange is sometimes referred to as a blanking flange. Experienced professionals are engaged with us who fabricate these flanges with excellent precision. We are recognized blind flanges manufacturer. ANSI B 16.5 Class 150 ANSI B 16.5 Class 300 ANSI B 16.5 Class 600 ANSI B 16.5 Class 900 ANSI B 16.5 Class 1500 ANSI B 16.5 Class 2500 Grades F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H,904L, Duplex stainless steel UNS S31803, 2205, Super Duplex stainless steel UNS S32750 Stainless Steel ASTM A 182, A 240 Nickel Alloys Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy C22,C276 Carbon Steel ASTM A 105, ASTM A 181 Alloy Steel ASTM A 182, GR F1, F11, F22, F5, F9, F91 Copper Alloys Copper, Brass & Gunmetal Size 1/8" NB TO 48"NB. Class 150#, 300#,400 #,600#,900#, 1500# & 2500 #. ANSI ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 DIN DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673 B.S BS4504 , BS4504, BS1560, BS10

Size : 1/2"NB TO 48"NB IN Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS Type : Seamless / ERW / Welded / Fabricated Material Type : Stainless Steel, Alloy Steel and Carbon Steel Nickel Alloys Duplex Grades : Nickel Alloy ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) Stainless Steel ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H. Duplex Steel ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760. Carbon Steel ASTM / ASME A 234 WPB, WPC ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. Alloy Steel ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91.

Size : 1/2"NB TO 48"NB IN Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS Type : Seamless / ERW / Welded / Fabricated Material Type : Stainless Steel, Alloy Steel and Carbon Steel Nickel Alloys Duplex Grades : Nickel Alloy ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) Stainless Steel ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H. Duplex Steel ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760. Carbon Steel ASTM / ASME A 234 WPB, WPC ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. Alloy Steel ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91.

Size : 1/2"NB TO 48"NB IN Schedule: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS Type : Seamless / ERW / Welded / Fabricated Material Type : Stainless Steel, Alloy Steel and Carbon Steel Nickel Alloys Duplex Grades : Nickel Alloy ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 ) Stainless Steel ASTM / ASME SA 403 GR WP "S" / "W" / " WX" 304 , 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H. Duplex Steel ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760. Carbon Steel ASTM / ASME A 234 WPB, WPC ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70. Alloy Steel ASTM / ASME A 234 WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 23, WP 91.

Page Links |

||||